What Is a Cleanroom? The Complete Beginner’s Guide

A cleanroom is a controlled environment designed to minimize contamination from dust, airborne microbes, and chemical vapors. Industries like electronics manufacturing, pharmaceuticals, biotechnology, and aerospace rely on cleanrooms to ensure product quality and safety.

If you are new to cleanrooms or considering setting one up for your business, this guide will explain the basics, types, key features, and real-world applications.

What Is a Cleanroom?

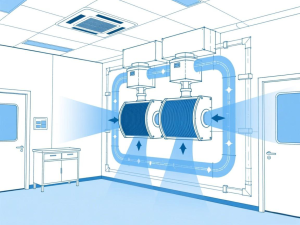

Cleanrooms are specially designed spaces that control environmental factors such as air cleanliness, temperature, humidity, and pressure. They use HEPA or ULPA filters to remove microscopic particles and prevent contamination.

- Controlled air quality with minimal particle count

- Temperature and humidity management

- Strict entry and operational protocols for personnel and materials

Types of Cleanrooms

Cleanrooms vary depending on industry needs:

1. Electronics Cleanrooms

Used in semiconductor and precision electronics manufacturing where dust or static can damage components.

2. Pharmaceutical Cleanrooms

Maintain sterile conditions for drug production, preventing microbial contamination.

3. Food & Beverage Cleanrooms

Ensure hygiene in food processing and packaging environments.

Cleanrooms are also classified under international standards like ISO 14644, which ensures consistency in cleanliness levels worldwide.

Key Features of a Cleanroom

- Air Filtration: HEPA or ULPA filters remove airborne particles.

- Pressure Control: Positive or negative pressure prevents contaminants from entering.

- Environmental Control: Temperature, humidity, and static electricity are regulated.

- Personnel & Material Protocols: Special gowns, gloves, and restricted access reduce contamination risks.

Applications of Cleanrooms

- Semiconductor and electronics manufacturing

- Pharmaceutical production

- Biotechnology laboratories

- Aerospace component assembly

- Medical device production

Why It Matters for Your Business: A well-designed cleanroom improves product quality, ensures regulatory compliance, and reduces contamination risks, protecting your brand reputation.

Conclusion

Cleanrooms are essential for industries requiring high standards of cleanliness. Whether in electronics, pharmaceuticals, or biotech, a properly designed cleanroom enhances efficiency and ensures product safety.

Contact Our Experts Today for a tailored cleanroom solution.