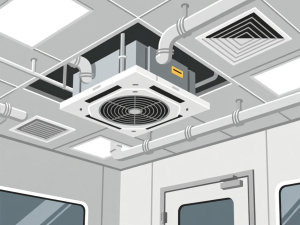

Air Handling Units (AHU) — Customized Cleanroom HVAC Systems

Customized Cleanroom HVAC

Air Handling Units (AHU) — Customized Cleanroom HVAC Systems

Precision AHUs engineered for controlled environments: superior filtration, accurate environmental control, and reliable operation for critical industries.

Why choose a customized AHU for your cleanroom?

Standard AHUs rarely meet the strict requirements of cleanrooms used in pharmaceutical production, semiconductor fabs, or battery manufacturing. A customized AHU ensures:

- Appropriate filtration levels (HEPA / ULPA) and validated airflow patterns

- Precise temperature & humidity control to process tolerances

- Low-vibration design to avoid contamination and protect sensitive equipment

- Energy-efficient components and optional heat/energy recovery

- Modular sizes for easy installation and future expansion

Key features of our Cleanroom AHUs

High-efficiency filtration

HEPA / ULPA filter stages, MERV pre-filters and downstream monitoring ports for filter integrity checks.

Precise environmental control

PID or advanced PID + Fuzzy logic control for ±0.5°C and tight RH control to meet process specs.

Low vibration & acoustics

Vibration-isolated fans, soft-start drives, and acoustic lining to reduce particle generation and noise.

Modular & pre-fabricated

Skid-mounted or sectional designs for fast on-site assembly and reduced lead times.

Technical specifications (typical)

- Airflow range: 500 — 50,000 m³/h (customizable)

- Filter: MERV8 pre-filter + HEPA H14 / ULPA U15 options

- Fan: Backward-curved / EC / IE4 motor options

- Controls: PLC / BMS-ready, Modbus / BACnet integration

- Construction: 304/316 stainless steel or coated carbon steel panels

Benefits for procurement & operations

Lower total cost of ownership — energy recovery wheels, variable-speed drives, and optimized ductwork reduce operating cost. Faster validation — modular design and accessible filter sections simplify commissioning and ISO validation.

Industry use cases: pharmaceutical cleanrooms (aseptic filling), semiconductor front-end fabs, laboratory HVAC, battery cell assembly.

How we customize AHUs — a simple process

- Requirement analysis: review ISO class, process heat load, latent loads, and contamination control needs.

- Proposal & sizing: airflow calculations, filtration selection, and energy recovery options.

- Manufacture & FAT: factory acceptance testing with performance certificates.

- Delivery & installation: site assembly, commissioning, and validation support.

Need detailed drawings, performance curves, or validation documentation? We provide full technical package on request.

Frequently asked questions (FAQ)

Can AHUs handle ISO 5 / Class 100 environments?

Yes — with properly designed airflow, terminal HEPA filtration and validated leak-free construction, AHUs can serve ISO 5 through ISO 8 cleanrooms when combined with the right terminal equipment (FFUs / laminar flow hoods).

What is the difference between HEPA and ULPA?

HEPA H14 filters capture ≥99.995% of 0.3 μm particles; ULPA filters offer even higher efficiency for submicron particles. Choice depends on process contamination tolerance.

Ready to specify your AHU?

Our engineers specialize in turnkey cleanroom HVAC packages. For quotes, CAD drawings, and lead-time information, Contact Us